How Digital Transformation in Logistics is Leading To Business Success?

Do you agree that digital transformation in logistics can elevate business growth and directly impact sales?

Well, 75% of logistics company leaders said that companies still aligned with legacy approaches in logistics and transportation are not just endangering their businesses but also struggling hard to meet today’s demands for speed and excellence!

Whether you are handling the warehouse with an outdated system or trying to venture into the logistics and transportation business, adopting to latest approach can help you unlock new business opportunities.

Digitizing logistics can help you eliminate all manual processes, deliver automated operational processes, and provide a satisfied customer experience. Though the logistics sector is digitally advanced in some ways, there is still a significant gap that needs to be addressed by adopting the right technology-driven approach.

Now the straight question arises here is what challenges or issues to be addressed with the digital transformation of logistics operations?

Here are the few major hurdles in the logistics industry that businesses are facing with outdated systems:

- Inefficient supply chain management, which leads to delays, over cost, and dissatisfaction, results from poor coordination and outdated systems that lack process management.

- Lack of access to real-time data can hamper effective decision-making in warehouse and inventory management. This leads to discrepancies and operational disruptions.

- Businesses are still relying on outdated systems or traditional manual processes that create inefficiencies, slowing down operations and hindering a company’s ability to stay competitive.

- Further, managing logistics with traditional and outdated systems often increases operation costs, and manual processes demand more time and resources.

- Another major challenge for businesses in logistics is warehouse management issues that require automation. The inefficiency of automation restricts businesses from making data-driven decisions, which leads to delays in picking, packing, and shipping. Overall, this whole process is the backbone of the logistic business that directly impacts your sales.

Why Digital Transformation In Logistics Has Become Crucial For Businesses?

Digital transformation in logistics is nothing but the process of integrating advanced technologies and tech trends into your business module to automate various aspects of logistics. From inventory management to warehouse management system, and customer notifications to real-time shipping tracking, you can modernize various aspects of the supply chain and logistics business.

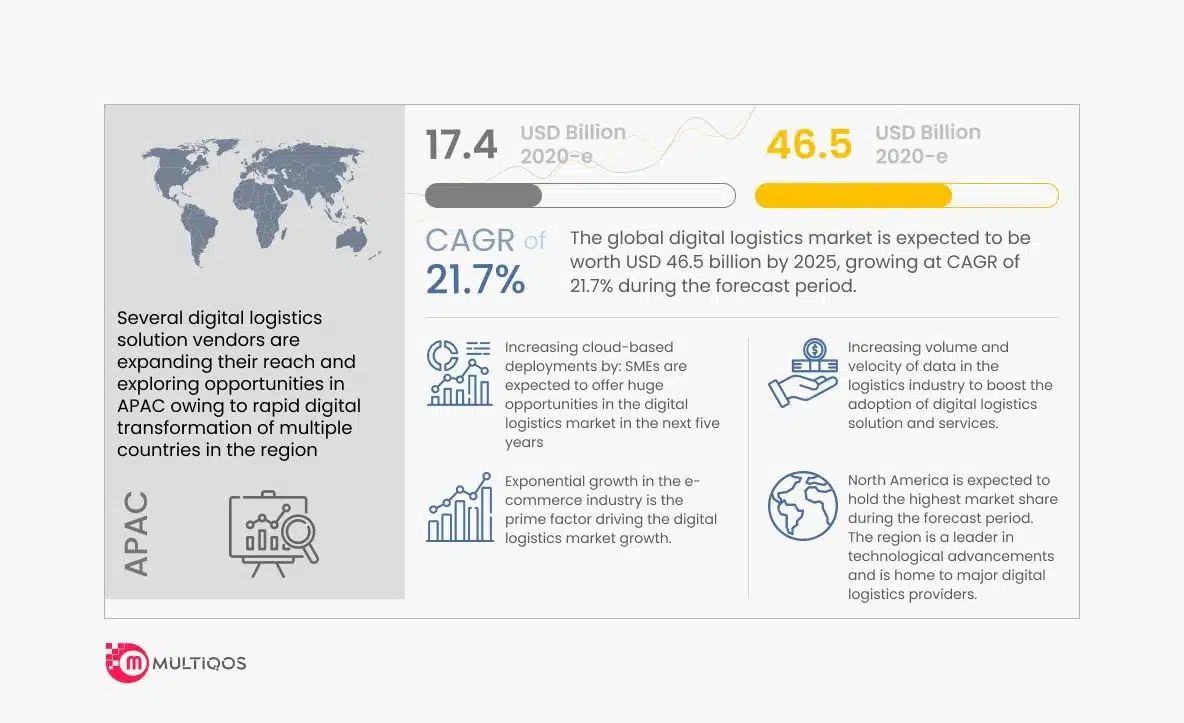

If you are still in doubt about hiring a mobile app development company USA to transform your logistics business then take a look at the market growth rate and digital adoption transformation statistics.

Impact of Digital Transformation on Logistics

- The report says that the worldwide expenditure on digital transformation is expected to reach $3.4 trillion by 2026.

- Organizations that are actively migrating their work module to digital platforms are six times more likely to achieve success.

- Moreover, it is expected that $100 trillion will be added to the world economy through digital transformation by 2025. And the tractions driven by digital platforms are expected to be roughly two-thirds of the $100 trillion by 2025.

- According to the market reports, the global digital logistics revenue will hit $46.5 billion by 2025 and is expected to grow at 21.7%.

In a nutshell, these figures represent that modern businesses are relying excessively on advanced logistics systems and making the industry rise to the next level. Apart from that, businesses are smartly spending on digital transformation services to stand out in the competitive landscape. And enterprises in the supply chain domain are no different.

What Are the Core Benefits of Digital Transformation in Logistics?

The digital transformation in logistics is a game changer for businesses handling ecommerce, transformation, supply chain, warehousing, and more. To understand what it contributes to your business, it is worth diving into these businesses to embrace the change.

1. Improved Operational Efficiency With AI-powered Analytics

Digitization can help logistic companies streamline their operations by leveraging advanced technologies like Cloud-based software and AI-powered analytics.

Unlike manual processes for managing and handling operations, it centralized the tracking of fleets and inventory, offering real-time data for decision-making and automating manual processes.

The small practice of digital transformation in logistics will lead to higher efficiency and reduced overall operational delays. At last, logistics operations run smoothly with consistent performance and optimized workflows across the supply chain.

2. Real-Time Shipment Tracking

One of the most significant benefits of digital transformation is the ability to track shipments in real-time. With customized logistics applications integrated with real-time shipment tracking features, both customers and businesses can gain full visibility into the status of shipments from start to finish.

Having real-time updates about the shipments can increase trust bring transparency into the logistics process and improve customer satisfaction.

This is where MultiQoS uses Shipping Tracking REST API in their logistics solutions to help you track more than 20,000+ shipments with detailed information. Moreover, our customized solutions can automatically add tracking information, send updates, and update orders with shipping carriers and fulfillment status.

3. Route Optimization with GPS Tracking

The digital logistics solutions work with advanced GPS-powered navigation systems that efficiently plan and optimize routes for logistics vehicles.

Digital tools help drivers select the best route for deliveries and minimize the risk of delays by early detecting traffic or roadblocks.

In addition, it not only improved the delivery times but also reduced fuel consumption and transformation costs, contributing to overall cost savings and improved fleet management.

4. Seamless Fleet Supervision with Predictive Maintenance

Digital transformation brings AI-powered predictive maintenance tools that create a buzz in the supply chain and logistics domain. It allows fleet managers to monitor vehicle performance remotely and able to detect potential issues early, which allows for timely repairs and preventive maintenance.

Did you know that unexpected vehicle breakdowns in logistics cost businesses over $80 million in annual loss by hampering their productivity, delaying shipments, and repair expenses?

With predictive maintenance, businesses can minimize vehicle downtime and reduce repair costs, while also ensuring the fleet operates smoothly and efficiently.

5. Improved Decision-Making

As the logistics sector expands, businesses have seen an enormous increase in data that is hard to scrutinize with manual procedures. Consequently, this highlights the need to invest in advanced analytical tools and techniques that help you access better insights and extract meaningful data for improved decision-making.

The world’s biggest logistics company, DHL, is the best example to consider. By embracing AI-powered analytics and big data to revolutionize its operations, DHL witnessed improved decision-making through digital transformation in logistics.

This small alteration to their operations has helped them predict potential delivery route delays due to weather conditions, traffic, or other disruptions. This allows them to reroute vehicles more efficiently and avoid unnecessary downtimes.

In a nutshell, automation in logistics can revolutionize the way you handle operations and predict future demand and supply. However, to reap the best potential of digitization in logistics will require you to hire a mobile application development company in USA that help you embrace the right choice of technology trends to streamline operations in logistics.

Latest Technology Trends Used For Driving Digitization in Logistics

Adopting to right digital technologies in logistics is important to embrace business transformation across this sector. So here we have gathered a few top technology trends used in the logistics industry for transforming traditional processes and operations.

1. Optimizing Operations With Artificial Intelligence (AI) and Machine Learning (ML)

With the way AI and ML are translating complex processes into automated operations, modern logistic companies have started relying on these top technologies.

But the question is how does it work and what exactly you can revolutionize by hiring an AI developer ?

AI and ML models are trained to analyze vast amounts of data collected across logistics operations such as delivery times, demand patterns, and traffic conditions. AI-powered algorithms use this data to identify trends, predict future demand, and suggest optimal routes and inventory levels. In addition, machine learning improves over time as it learns from historical data and makes predictions more accurately.

Whether you are into logistics businesses or trying paving into the same sector, MultiQoS can be your trusted tech partner in transforming your logistics business by developing AI-driven solutions tailored to your specific needs. Our expertise in AI and ML development services makes us stand apart in the automation of complex workflows like demand forecasting, route optimization, and warehouse man

2. Robotics and Automation in Logistics

Gone are those days when end-to-end logistics operations would require a humanized workforce. According to reports, 69% of day-to-day managerial work will be automated by the end of 2024.

Robotics and Automation in logistics involve deploying advanced technologies such as autonomous mobile robots (AMRs), drones, and automated guided vehicles (AGVs) to perform routine tasks.

These robots can navigate warehouses autonomously, picking and packing items, sorting goods, and moving inventory with precision. They are powered by AI algorithms, sensors, and machine learning models, which help them interact with their environment and complete tasks without any human interventions.

The ultimate results of automation in logistics with robotics is it reduces manual tasks, enhances accuracy, speeds up operations, and lowers operational costs.

Contribution of MultiQoS in Providing Robotics Support and Automation in Logistics:

We specialize in logistics software development that support robotics and automation in logistics. We create intelligent systems that integrate with autonomous robots, AVGs, and drones. It helps businesses to automate repetitive tasks like order picking, packing, and transportation procedures.

3. Using Predictive Analytics and Big Data for Predicting Demands

Predictive analytics leverages big data and uses advanced algorithms to analyze historical trends and real-time data gathered from various resources like sales records, customer interactions, and shipment histories.

Identifying patterns helps logistics businesses predict future demand, adjust inventory levels, and foresee potential maintenance needs for equipment. This proactive approach minimizes the risks like stock shortages, excessive inventory, and unexpected breakdowns.

If you are also chasing all these challenges, then MultiQoS can help you create a custom platform that is seamlessly integrated into your existing system. It will help you access analytics tools, offering real-time insights into demand forecasting, inventory management, and more.

Conclusion

By the end of this blog, it is fair enough to say that digital transformation in logistics has put the industry on boom. However digitizing logistics and transportation is challenging, expensive, and involves lengthy procedures and massive migration cycles.

This is where, if you are eyeing to transform your business, then hire mobile app developers to accelerate your logistics and transportation operations by enabling technology end-users with contextual guides end-users or complex processes. If you are all set for your digital transformation journey, then drop your details below or contact us directly for the estimations that validate your requirements.

Frequently Asked Questions

Digital Transformation in logistics refers to the process of integrating the latest technology trends into the business model to automate operations, improve efficiency, enhance decision-making, and minimize operational costs

Digital transformation helps logistics companies minimize their manual processes and lets them automate repetitive tasks by using robotics and automation. Further, improves the efficiency of making data-driven decisions to avoid overstocking and out-of-stock situations by using predictive analytics and more.

MultiQoS is a top mobile app development company in USA, specializing in crafting solutions that support various industries, and logistics and transportation are not an exception. By analyzing your business challenges, we validate your app idea and find the scope of implementing the right technologies like automation, robotics, AI and ML algorithms, and more.

The average cost of transforming logistics operations digitally will range between $20,000 to $30,000+, depending upon the complex requirements and timeline. Though, these are the rough estimations that can go above and below vary based on your business requirements.

Get In Touch