AI In Inventory Management: A Must-Have Guide for Smarter Stock Control

Introduction

Did you know businesses can lose about 4% of overall sales due to stockouts, as customers may abandon purchases when items are unavailable? Or are you still relying on outdated methods to manage your inventory? If so, it’s time to rethink your approach, as AI in inventory management is revolutionizing how companies maintain stock levels and predict demand. In today’s fast-paced market, leveraging AI based inventory management is not just an advantage but a necessity.

This article will highlight the significant benefits of using AI for inventory management, including improved accuracy, reduced overhead costs, and enhanced customer satisfaction. By the end, you’ll understand how adopting these cutting-edge technologies can boost your business’s efficiency and profitability.

What is AI Inventory Management?

AI in inventory management leverages advanced algorithms and machine learning to optimize stock levels, forecast demand, and enhance overall supply chain efficiency. By analyzing historical sales data and market trends, artificial intelligence in inventory management enables businesses to make data-driven decisions that minimize overstock and stockouts.

This proactive approach reduces operational costs and improves customer satisfaction by ensuring that products are available when needed.

AI inventory management software provides real-time insights into inventory performance, allowing organizations to respond swiftly to changing market conditions. Imagine a scenario where your system predicts a surge in demand for a seasonal product weeks in advance, prompting automatic restocking orders.

This predictive capability transforms AI inventory management from a reactive process into a strategic advantage, empowering companies to maintain an agile supply chain. Ultimately, embracing AI inventory optimization in this realm not only streamlines operations but also fosters innovation, paving the way for smarter business practices in an increasingly competitive landscape.

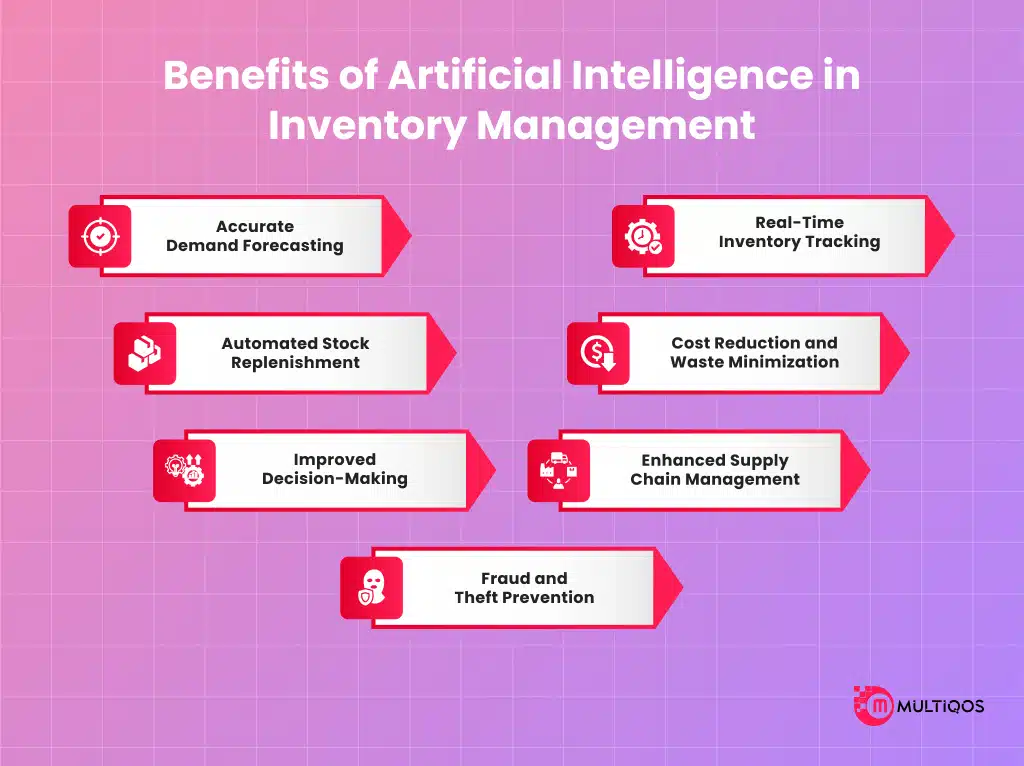

7 Key Benefits of Artificial Intelligence In Inventory Management

AI and inventory management are transforming the way businesses handle stock control, optimize resources, and improve operational efficiency. By leveraging AI, companies can reduce errors, enhance forecasting accuracy, and streamline supply chain processes. Here are the seven key benefits of AI in warehouse management:

1. Accurate Demand Forecasting

AI inventory management uses historical sales data, market trends, and seasonal fluctuations to predict future demand with high accuracy. ML algorithms analyze patterns in customer behavior, economic conditions, and even external factors like weather and competitor activity.

This helps businesses maintain optimal stock levels, reduce stockouts, and minimize overstocking, ultimately improving cash flow, reducing losses, and enhancing customer satisfaction by ensuring product availability.

2. Real-Time Inventory Tracking

AI-integrated IoT sensors and RFID technology enable real-time tracking of inventory AI across warehouses, retail locations, and distribution centers. These smart tracking systems continuously update stock levels, providing businesses with accurate, real-time visibility into inventory status.

This reduces discrepancies, minimizes human errors, and enhances operational efficiency by allowing managers to make informed decisions regarding restocking and distribution. Also, real-time tracking reduces product misplacement and shrinkage, ensuring better asset management.

3. Automated Stock Replenishment

AI for warehouse management systems can automatically trigger stock replenishment orders when inventory levels fall below a predefined threshold. Advanced AI models analyze sales trends and supplier lead times to place replenishment orders at the right time, ensuring uninterrupted supply chain operations.

Automation reduces manual workload, prevents over-ordering, and minimizes the risk of stockouts, leading to better efficiency in warehouse operations and improved customer service. AI-driven replenishment can prioritize high-demand products, ensuring faster inventory turnover.

4. Cost Reduction and Waste Minimization

AI optimizes inventory management by reducing excess stock, minimizing carrying costs, and preventing unnecessary storage expenses. By accurately predicting demand, businesses can avoid over-purchasing slow-moving products and minimize waste, particularly for perishable goods like food and pharmaceuticals.

AI-driven insights help retailers implement just-in-time (JIT) inventory strategies, reducing holding costs while ensuring product availability. This results in lower operational expenses, improved profit margins, and more sustainable inventory practices.

5. Improved Decision-Making

AI-driven analytics provide actionable insights into sales trends, customer preferences, supplier performance, and market demand fluctuations. By analyzing vast amounts of data in real time, AI helps decision-makers optimize pricing strategies, improve stock allocation, and enhance overall inventory planning.

Businesses can quickly adapt to changing market conditions and customer demands, reducing inefficiencies and improving profitability. Inventory management using AI can identify patterns that human analysis might overlook, enabling proactive decision-making and long-term strategic planning.

6. Enhanced Supply Chain Management

AI for inventory management enhances supply chain efficiency by optimizing logistics, warehouse operations, and route planning. AI-driven route optimization reduces transportation costs and ensures timely deliveries by analyzing traffic patterns, fuel consumption, and weather conditions.

Smart AI algorithms also streamline supplier coordination, reducing lead times and mitigating risks associated with supply chain disruptions. By providing end-to-end visibility, AI enables businesses to predict and respond to challenges before they impact operations, ensuring a smoother and more resilient supply chain.

7. Fraud and Theft Prevention

AI-powered surveillance systems, computer vision, and advanced data analytics can detect anomalies, unauthorized transactions, and suspicious activities in warehouses and retail stores. AI can identify unusual purchasing patterns, flag discrepancies in stock levels, and prevent internal fraud.

AI-based facial recognition and motion detection technologies enhance security by monitoring storage areas for unauthorized access. This reduces the risk of fraud, theft, and inventory shrinkage, safeguarding valuable assets and improving overall inventory accuracy.

AI Technologies Transforming Inventory Management

AI is revolutionizing inventory management by enhancing efficiency, reducing waste, and improving decision-making. Businesses leveraging AI in inventory management can optimize stock control, predict demand, and automate routine processes.

These advanced technologies help reduce human errors, improve order accuracy, and enhance supply chain efficiency.

Here are the top AI-driven technologies driving change:

- Predictive Analytics – AI analyzes historical data, market trends, and seasonal fluctuations to forecast demand accurately. This helps businesses maintain optimal inventory levels, preventing stockouts and overstock situations.

- Computer Vision – AI-powered image recognition enhances warehouse monitoring, enabling automated stock tracking, quality control, and damage detection. This minimizes human intervention and ensures accurate inventory management.

- Robotic Process Automation (RPA) – AI-driven bots streamline order processing, automate invoice management, and handle repetitive inventory tasks, reducing manual errors and operational costs.

- IoT and Smart Sensors – AI integrates with IoT devices to provide real-time inventory tracking, temperature monitoring for perishable goods, and automated restocking alerts. This improves supply chain visibility and responsiveness.

- Chatbots and AI Assistants – AI-powered virtual assistants enhance supply chain communication, helping teams manage inventory queries, reorder stock, and resolve logistical issues quickly.

- Autonomous Mobile Robots (AMRs) – AI-driven robots efficiently navigate warehouses, transport goods, and assist in picking and packing, boosting operational speed and accuracy.

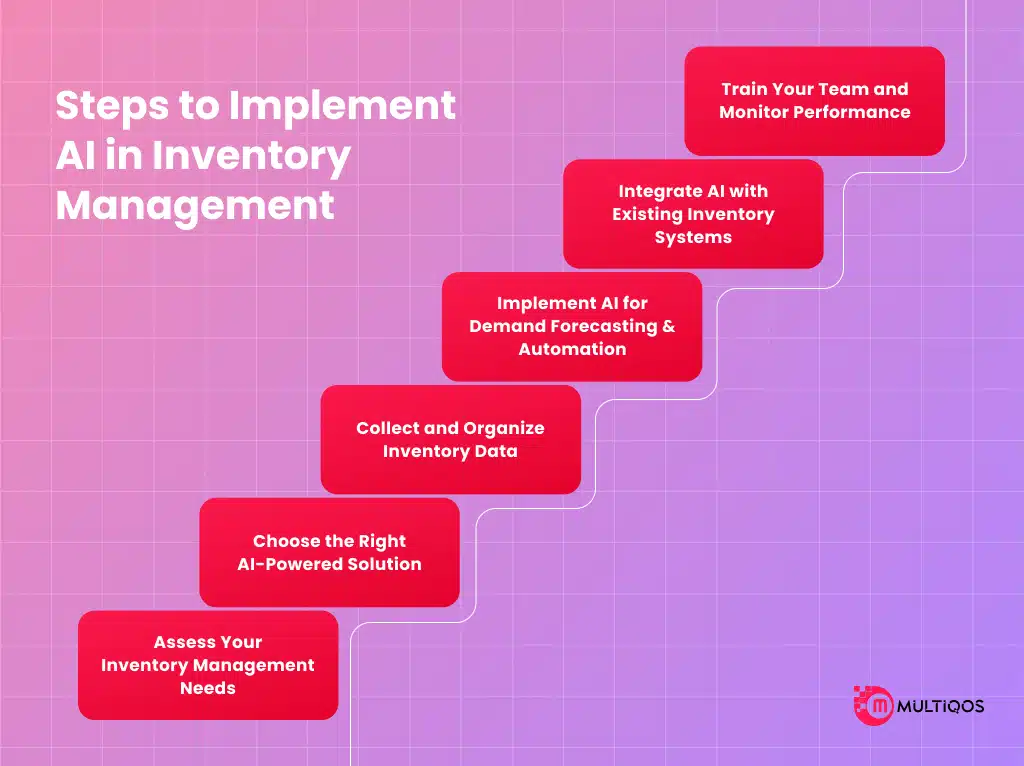

How Can You Implement AI In Inventory Management?

Implementing AI inventory management can revolutionize stock control, improve efficiency, and reduce operational costs. To successfully integrate AI, businesses must follow a structured approach to ensure smooth adoption and maximize its benefits.

Here’s a step-by-step guide on how to implement artificial intelligence in inventory management:

Assess Your Inventory Management Needs

Before adopting AI stock management, evaluate your current inventory management challenges and goals. Identify pain points such as stock discrepancies, demand fluctuations, or supply chain inefficiencies.

Determine which AI-driven solutions—such as demand forecasting, automated restocking, or real-time tracking will provide the most value for your business.

Choose the Right AI-Powered Solution

Selecting the right AI inventory management system is crucial for success. Consider solutions that align with your business size, industry, and operational needs. Look for AI tools that offer predictive analytics, automation, and seamless integration with your existing infrastructure.

With the growing influence of AI in mobile app development, businesses can also leverage AI-powered inventory management apps for real-time tracking, automated restocking, and data-driven decision-making. Cloud-based AI solutions further enhance flexibility and scalability for growing businesses.

Collect and Organize Inventory Data

AI relies on accurate and well-structured data for optimal performance. Gather historical sales data, supplier details, and real-time inventory records. Make sure the data is clean, standardized, and easily accessible for AI processing.

Integrating IoT sensors, barcode scanners, and RFID technology can further enhance data accuracy and visibility.

Implement AI for Demand Forecasting & Automation

Deploy AI-powered demand forecasting models to predict inventory needs based on historical trends, customer behavior, and market conditions. Automate routine inventory tasks such as stock replenishment, order processing, and warehouse tracking.

AI-driven automation reduces human errors, optimizes stock levels, and improves overall efficiency.

Integrate AI with Existing Inventory Systems

For seamless operation, AI tools should integrate with your existing Enterprise Resource Planning (ERP) or inventory management systems.

API-based integrations allow AI inventory management solutions to work in sync with other business applications, ensuring real-time updates, efficient supply chain coordination, and smooth workflow management.

Train Your Team and Monitor Performance

AI implementation is most effective when employees are equipped with the right knowledge and skills. Train your team on how to use AI tools, interpret insights, and adapt to new workflows.

Continuously monitor AI performance, track key performance indicators (KPIs), and gather feedback to make necessary adjustments.

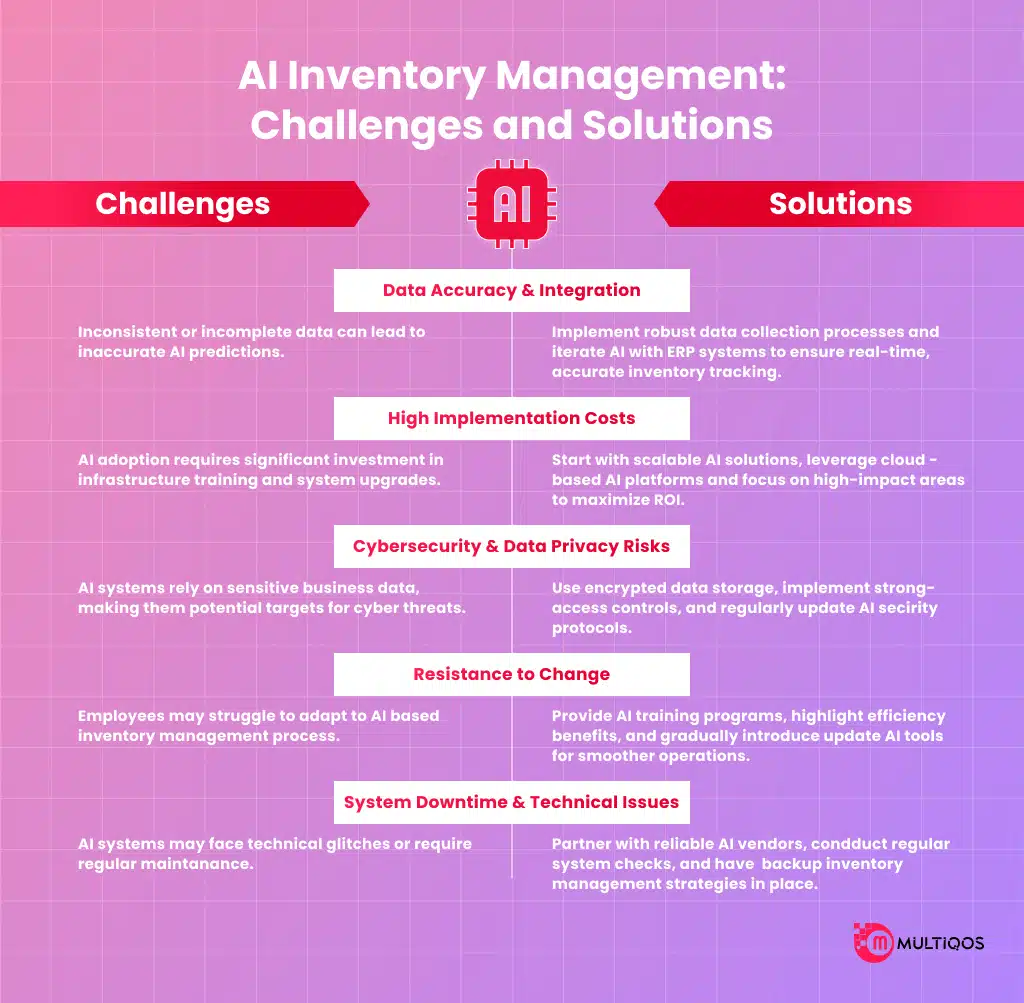

AI Inventory Management: Challenges and Solutions

While AI is transforming inventory management with automation and predictive analytics, businesses still face challenges such as data accuracy issues, high implementation costs, and cybersecurity risks. Overcoming these obstacles requires strategic solutions like robust data integration, scalable AI investments, and enhanced security protocols.

Below are some key challenges and their solutions to ensure the successful adoption of AI inventory management.

Conclusion

To wrap up, the incorporation of AI in inventory management marks a major advancement toward smarter stock control. By leveraging real-time data analysis, AI empowers businesses to anticipate customer demands and adapt quickly to market shifts. Partnering with an AI development company ensures seamless implementation, allowing businesses to optimize inventory processes and enhance overall efficiency.

This proactive approach not only minimizes waste but also enhances customer satisfaction by ensuring product availability. As we look ahead, it’s clear that businesses prioritizing inventory AI integration will thrive in an increasingly complex marketplace. Take action now, hire AI developers, and transform your AI inventory management software development strategy for sustained success!

Frequently Asked Questions

AI in inventory management refers to the use of artificial intelligence technologies, such as machine learning, predictive analytics, and automation, to optimize stock control, demand forecasting, and supply chain efficiency. It helps businesses reduce waste, prevent stockouts, and improve operational efficiency.

Simply contact us via our website, email, or phone. Our experts will analyze your inventory management needs and recommend the best AI developers and solutions for your business.

The process includes:

- Consultation – Discuss your inventory management needs with our experts.

- Requirement Analysis – We assess your project scope, AI features, and integration needs.

- Developer Selection – Choose from our pool of skilled AI developers or dedicated teams.

- Engagement Model Selection – Opt for full-time, part-time, or project-based hiring.

- Project Kickoff – Our developers start working on AI implementation and integration.

- Ongoing Support – We provide post-development maintenance, updates, and optimizations.

Yes, MultiQoS allows you to interview developers, review their expertise, and select the best fit for your project before finalizing the hiring process.

Get In Touch