IoT Based Predictive Maintenance: The Ultimate Guide

Introduction

As competition and costs are rising daily, companies are trying to avoid the idle time of their production units. This is due to the repair and maintenance of machines. Organizations are staying on track with the maintenance process and have embraced the technological boom of the Internet of Things or IoT.

Today with the help of IoT, organizations can predict and take care of their production machines. It is time to know about them a bit so you can gear up with your productions without glitches.

What is Predictive Maintenance?

Companies follow the maintenance process described by the manufacturers when the machines are bought. It may be scheduling maintenance after the machines have worked for some hours, weeks, or months. Again, many manufacturers ignore more minor signs and only maintain the machines when they are utterly broken down.

It not only hampers the production processes but also burns a big hole in their pockets. Thus, the workers have no work to do. It is not a cost-effective idea but eats away the percentage of profit. Industrial units often fall into the dilemma of when to maintain the machines. However, predictive maintenance using IoT is the in-thing with technological advancement.

Today, it is more predictive maintenance than preventive maintenance. Predictive maintenance is done when necessary, depending on the condition of the assets. Here’s how it helps:

- Things become easy if one can predict the risk of breakdown, malfunction, or failure of the machine. With industrial machines becoming complex these days, it is not always possible for workers to predict failures. Thus, many companies have embraced the new technology of industrial IoT predictive maintenance whereby the condition of the assets is continuously monitored through data collection and analysis.

- Today, IoT and predictive maintenance are like the hand and the gloves. This is because the IoT-based systems connected with the assets help to predict, plan and take proactive actions to avoid a complete breakdown of the assets.

- Shop floor managers can now take maintenance and repair work getting the slightest signs using IoT or even long before the occurrence of failures, if any. IoT predictive maintenance is performed when the machines are working in normal conditions so there is no disruption in business.

What is the Role of IoT in Predictive Maintenance?

Today, IoT plays a pivotal role in predictive maintenance. Here how:

-

Address potential issues and safety risks

IoT-based predictive maintenance helps production units to anticipate and address potential issues and safety risks before they happen. Through IoT predictive analytics, shop floor managers can take action without compromising the safety of the workers. This is because data is available from multiple sources through the IoT devices connected with the assets.

-

Estimate the impact on daily working

Companies look at the industrial IoT predictive analytics over the most extended possible periods, decide on the hazardous working conditions and estimate the impact on daily working so that the machines can be maintained adequately without any delay. It helps to relocate the resources and optimize the threshold limits of exposures adhering to the working rules and regulations.

-

Constant equipment monitoring

As the equipment is constantly monitored through IoT, the unscheduled downtime is minimized, thus improving overall operations. The pieces of machinery stay in good health with IoT for predictive maintenance.

-

Data analysis to take corrective measures

The data is captured in digital form through IoT and then transmitted to the server for storage and evaluation. Predictive maintenance industrial IoT experts analyze the data. They calculate the probabilities for the occurrence of various specific events at a given time. This way, corrective measures are taken.

The sensors gather real-time data across various assets and systems so that manufacturers can anticipate malfunctions and plan for events such as probable breakdowns and replacement of spare parts before things go out of control or the machines wholly shut down.

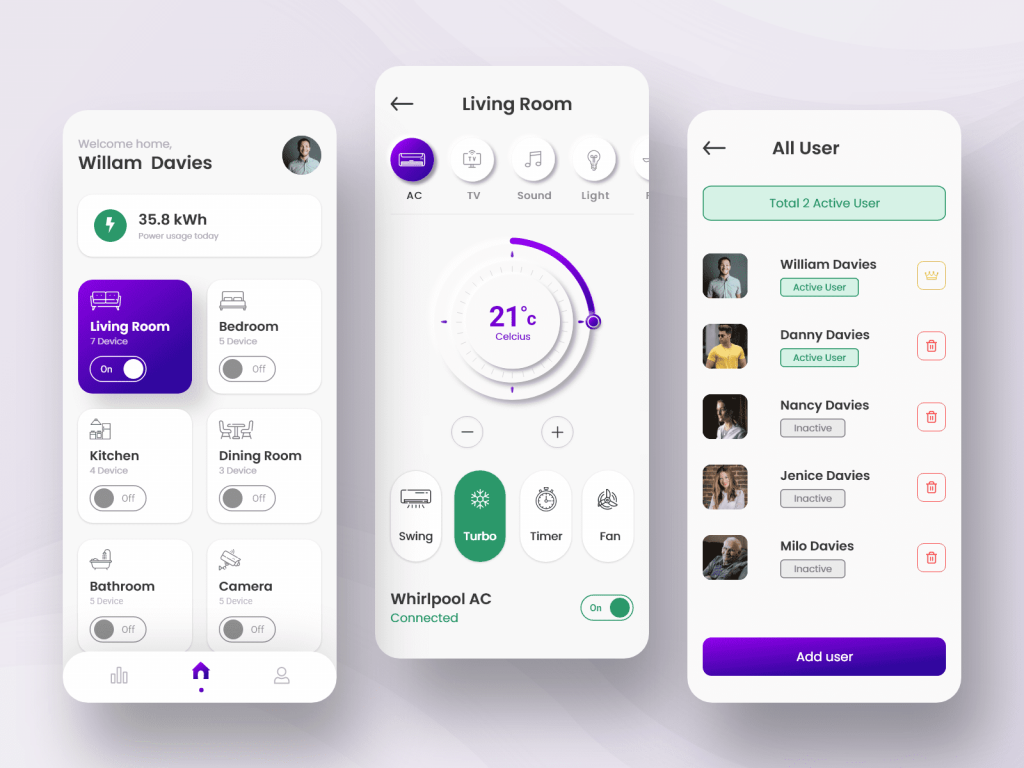

Source: Smart Home IoT App Design

Benefits of IoT-based Predictive Maintenance

There are multiple benefits to predictive maintenance and IoT. The faults can be predicted in real-time and taken care of before conditions become critical or go out of hand. The maintenance while the equipment is still functional. It cuts down the cost to a great extent and interrupts operations.

Studies have shown that unplanned downtown costs can go up to US $ 50 billion yearly. It can be drastically cut down with IoT maintenance predictive analysis.

- Enhances equipment life: With predictive maintenance IoT systems, manufacturers can extend and improve the life of the equipment.

- Enhancing the quality of production: The overall productivity and quality improved significantly, and the return on investment increased to about 83% in a year. All becomes possible by minimizing downtime, enhancing the safety of the workers, and cutting down maintenance costs with the help of IoT.

- Helps to identify weak areas: As the information is gathered in real-time, it becomes easy for the IoT app development services department to determine the inefficient areas so that the production system can be improved to a much greater extent. Identifying inefficient areas and rectifying those cuts down production costs, thus giving more positive returns on investments.

- Helps to speed up the decision-making process: As the IoT devices are connected to the machines and data is transferred in real-time, the analyzers can speed up the decision-making process, which is very much needed for predictive maintenance. Entrepreneurs and managers can make logical and well-informed decisions in a quick time. Thus many companies hire IoT developers to keep track of predictive maintenance and do the needful without losing much time.

- Reduces downtime: The operators become more proactive in identifying the faults, thus, it reduces downtime. The data can provide all machine health parameters and get them analyzed. Then, it’s passed on to the maintenance team to take quick action.

Predictive Maintenance by Industries

Predictive maintenance is the key to success if the industry is asset oriented for production.

- Today, companies like electricity distribution, power generation, or any other emergency and heavy industries, big or small, are relying on predictive maintenance with the help of IoT.

- Oil and gas companies are outsourcing a reputed IoT application Development Company for real-time information on their assets to minimize disruptions during environmental disasters and maximize profits.

- Manufacturing industry units hire dedicated developers if they have a significant operational area and the scope of work is much extended. Again the best Internet of things Development Company works for many industries and installs IoT devices. It analyzes so that the end users can get the best results.

- IT industrial units are tying up with the best mobile app development company in new jersey to do predictive maintenance of their assets and increase business.

Tools For Predictive Maintenance: Best Practices

Predictive maintenance and analysis can be done through various tools. Through each of the tools, the analyzers can make proper decisions. These tools involve:

- Motor Circuit Analyzers

- Laser-shaft alignment tool

- Sensors for vibration analysis

- Sensors for Infrared Analysis

- Microphone for Ultrasonic analysis

Conclusion

Without a robust predictive maintenance practice and strategy, carrying on with the business without much disruption is impossible. The focus has shifted from preventive maintenance to predictive maintenance, and IoT is the big game changer.

The results are much more accurate. Also, organizations can plan their production accordingly by analyzing the real-time data received with the help of IoT. It is time to embrace new technology and look forward to more positive investment returns.

Want to Build an IoT App to Make Your Business Smarter?

We provide industry-specific IoT applications to generate value and tackle unique business challenges.

FAQs on IoT For Predictive Maintenance

With IoT, it is possible to continuously monitor the working of mechanical assets and get real-time data to analyze them.

Yes, the idle time can be reduced, and the machines can be rectified of faults. This is done by observing the minor defects that can otherwise burn a big hole in the pockets if ignored.

Any minor fault can be handled through predictive maintenance when clubbed with IoT. Thus, the workers are at less risk of accidents while working. Moreover, the safety feature is enhanced to a much greater extent.

Many big organizations either have their team for analyzing data or outsource the entire process of IoT and do the maintenance. It depends on the industry’s scale, the scope of work, and viability.

Get In Touch