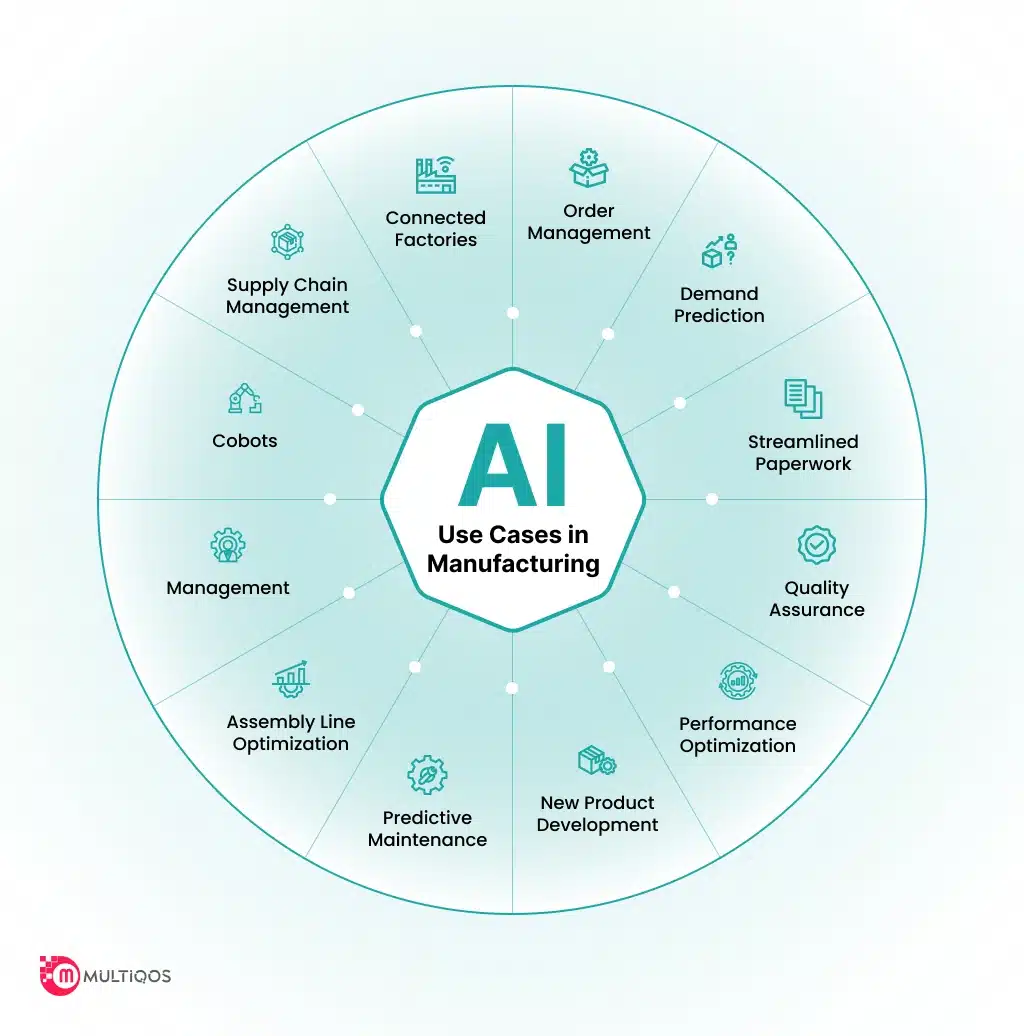

How AI is Transforming Manufacturing: 12 Key Use Cases

Table of Contents:

Introduction

Artificial intelligence, when applied in manufacturing, has many changes that help in its overall transformation. Most large manufacturing firms are applying AI as a competitive tool across the organization to work smarter and faster.

The application of AI in manufacturing provides companies with better use of data analytics, machine learning, and digital automation tools to innovate.

These new technologies present a revolutionary step from conventional techniques, providing manufacturers with opportunities to bring their business into the new age, to become more immediate, and to remain relevant in a market that never stays still for long.

In this article, we will discuss 12 key manufacturing cases of AI that are shaping future breakthroughs in productivity, inventions, and competitiveness.

These examples show how AI is being employed successfully in a range of ways to improve efficiency, product development, and the re-establishment of its existence in the supply chain and smart factory practices.

What is AI in Manufacturing?

In today’s manufacturing environment, industrial IoT and intelligent services create massive amounts of data daily. This data is increasingly being utilized by manufacturers via AI technologies consisting of machine learning (ML) and deep-gaining knowledge.

Perhaps one of the most giant uses of AI in manufacturing is in the prevention of system failure. This has the benefit of lowering maintenance costs and time on the production lines. AI also has other advantages; those include improved demand estimates and minimized waste.

The Impact of Artificial Intelligence in Manufacturing

AI is specifically useful in industries consisting of manufacturing because of its potential to manner and examine information accrued via IoT development and factories.

To effectively deal with this data, manufacturers are now employing and adopting AI technologies, including machine learning and deep learning neural networks, in order to make better decisions.

It is worth noting that AI is an indispensable tool in increasing output, capacity, and, in many ways, even the decision-making process. Quality control is another sector where the application of AI is highly effective. Through machine learning, systems are able to point out defects on products to make certain that only quality products get into the market.

Furthermore, AI tracks processes in smart manufacturing in real-time, offering solutions to optimize them and control resource wastage.

Summing up, the integration of artificial intelligence in manufacturing is becoming a key driver for change, increasing competitiveness and improving business processes.

As a way of increasing our knowledge of the results of using this era in manufacturing, underneath are some real examples of AI usage in production.

Top AI use cases in manufacturing: Increasing Efficiency and Innovation

AI is now one of the biggest disruptors within the production industry, as several organizations have leveraged it to provide performance in such a lot of factors in their enterprise. Here, we explore some of the top AI use cases that are revolutionizing the manufacturing industry:

1. Supply Chain Management

Supply chain management is very important in the manufacturing process, and this aspect has been boosted by the integration of artificial intelligence. The use of AI development in manufacturing includes demand forecasting, logistics, inventory management, and predictive analysis of data.

The commercial forecasting methods make use of the ML algorithms, which use past records to forecast the trends and variations in demand.

For instance, an automobile parts firm can employ the models in determining spare parts demand patterns so as to order in advance and consequently, minimize costs.

One of the good and successful cases is Walmart; it has introduced AI across its supply chain decision-making, responsiveness, and global supply chain management, thus making a benchmark in the highly competitive space of retail business.

2. Cobots

AI-enabled collaborative robots, or cobots, are a reality now and are assuming significant importance in manufacturing industries as assistants to human operators to increase efficiency.

Cobots work alongside humans in areas, thus picking and packing at fulfillment centers relying on AI for identification and negotiation of spaces.

For example, Amazon has integrated machine learning-mounted cobots that work as essential tools for advancing efficiency, streamlining the delivery processes, and easing flows.

This is the perfect blend of joining human input with the capability of artificial intelligence to show how, with manufacturing, more elements of flexibility and productivity can be brought to the top where operational excellence is achieved under the guidance of man and machine.

3. Management

The manufacturing industry also finds its use in warehouse management by means of artificial intelligence. Intelligent technologies such as AI have brought improvement in performance, efficiency, and quantity through the use of machine learning in a warehouse.

One of the main areas where AI can facilitate working in warehouses is stock maintenance and tracking. This will enable warehouses to strike the best balance between stock holding and stock out so as to retail products but minimize the cost of holding inventory.

4. Assembly Line Optimization

Several applications are being implemented in assembly lines by integrating AI to enhance accuracy, speed, and flexibility in production.

Performance history and real-time data from the sensors are allocated by the machine learning algorithms to optimize throughput, decrease drag time, and facilitate predictive maintenance.

One of the most powerful automotive companies, Volkswagen, currently employs AI technologies intended for the optimization of its production lines.

To monitor the assembly line, the company has installed sensors that feed real-time data to the machine learning algorithms to facilitate prediction of maintenance requirements and refine operating procedures with an aim of improving product quality and production effectiveness.

5. Predictive Maintenance

Predictive maintenance is an example of a big step in the manufacturing industry due to AI applications. With such systems in place, companies can set up alarms automatically and track equipment failure objectively.

Thereby keeping downtime to the minimum and ensuring that maintenance schedules are perfectly synchronized. This is done using more complex predictive analytics with applications in machine learning systems.

This is a more advanced approach to predictive maintenance since it involves utilizing artificial intelligence in monitoring the equipment, thereby resulting in cost savings and better efficiency in the performance of the equipment, among many other benefits.

These aspects of digital twins and checking on advanced analytics represent how AI is disrupting manufacturing industries through the application of data-driven decision-making and predictive maintenance solutions.

6. New Product Development

One of the more striking effects that has come about from implementing AI is seen in new product development across the manufacturing sector.

Another crucial area where AI is showing its potential is in the manufacturing processes and new product development, which are being revolutionized by such AI solutions.

For instance, machine learning in the semiconductor manufacturing line can be used to pinpoint weaknesses in designs to help engineers design around them or to accurately predict when a particular component is going to fail, as well as to suggest the best layout for ICs to increase the yield.

7. Performance Optimization

AI is also essential for enhancing the performance of the facility in the context of the manufacturing industry.

Since AI systems are capable of learning and making decisions based on data inputs, for example trends, sensor information, and other variables, it is possible for such systems to learn and determine possible trends, deviations, or forecast data.

Which in turn helps enhance overall equipment effectiveness, reduces equipment downtime, and hence improves the operational efficiency of manufacturers.

This is an indication of the usefulness of the AI systems in manufacturing and their ability to improve upon the performance of manufacturing companies, and hence a very important factor in identifying use cases within the manufacturing industries.

8. Quality Assurance

AI has also found its application in quality assurance, which is one of the other vital aspects of the manufacturing industry. With the help of such AI features, companies can be precise and use AI to increase the level of quality in the given processes.

Applying computer vision algorithms, manufacturers can use AI to analyze images or video clips of the product and the components. Such algorithms are much more effective when it comes to detecting defects and anomalies, as well as differences from standards than humans.

Through the use of AI in quality control, the manufacturing process is more efficient with high precision and quality, thus enabling companies such as Foxconn to meet clients’ needs in the fast-progressing electronics market.

9. Streamlined Paperwork

It also mentioned that AI and machine learning are also being used in manufacturing, mainly to automate paperwork via RPA. Earlier, all the processes within manufacturing, such as purchase orders, invoices, and quality control and testing documents, were largely paper-based.

Many of the tasks involved were manual, and as such, they took a lot of time, were inaccurate, and were highly likely to introduce a lot of delays.

For example, Whirlpool adopted the RPA methodology in the manufacturing environment to advance different operations such as assembly lines and material flow.

These RPA bots handle routine and standardized operations, making them precise in these undertakings. This is a clear implication that AI can be of great help in enhancing productivity while at the same time improving production quality.

10. Demand Prediction

The prediction of demand has risen to be one of the most significant fields in the manufacturing industry that is today being led by AI. Using the sales data of certain months and years, as well as factors that may exist outside the business sphere, AI can help in demand prediction and contribute to more effective business decisions.

For instance, a fashion retailer can utilize artificial intelligence to estimate the quantity of a certain type of cloth that is likely to be sold within a certain period.

The AI use case in demand prediction proves that artificial intelligence positively impacts the operational effectiveness and interactivity of the manufacturing industry and shows an example of how it affects the supply chain and business outcomes.

11. Order Management

AI is also in the process of transforming order management in the manufacturing industry by enhancing the process of order fulfillment. Based on past data, customer behavior, and other variables, machine learning algorithms can forecast demand, process orders, manage inventory, and establish variable rates.

Furthermore, AI increases the efficiency of fraudulent order prevention, which is a concern when placing an order online.

There is a real-life application of AI in order management that is called IBM Watson Order Optimizer. This AI/ML-based solution involves processing order history, client behavior pattern, and other variables for efficient order dispatch and inventory management to provide suitable order routing suggestions.

12. Connected Factories

One of the major real-world applications of AI in industries is connected factories, which generate smart, integrated networks throughout manufacturing processes.

Through IoT sensors, the manufacturer can gather data from the machines with the help of an AI tool that can be used to forecast different maintenance requirements, improve operations, and decrease unhealthy time.

This interrelated network supports a direct machine interface that supports quick rescheduling of production in relation to changing demands. Artificial intelligence in decision-making and operational efficiency optimizes business functioning and outcomes.

How MultiQoS AI Solutions Drive Manufacturing Success

MultiQoS AI Solutions in Manufacturing are reshaping the manufacturing industry by implementing deep artificial intelligence approaches to achieve daily operations. MultiQoS then allows companies to optimize their operations by implementing artificial intelligence into their manufacturing processes to maximize quality while reducing costs.

Its AI solutions incorporate a range of features, such as the use of artificial intelligence as a machine learning tool, natural language processing, and computer vision to enhance quality control through automation, predict equipment failure, and optimize production lines for manufacturers.

In addition, what makes the systems based on AI outstanding is that they will work efficiently, day and night, then give real-time results, which will simplify work processes and help to achieve more for less money.

Ready to take your manufacturing operations to the next level with AI? Contact MultiQoS today to explore how our innovative solutions can drive your success and revolutionize your industry.

FAQ on AI in Manufacturing

AI improves industrial productivity through inventory management, prediction and maintenance, and improving the quality of the product. It helps in making many decisions based on the data and promotes change in the whole sector.

Yes, AI enhances the quality of the products and minimizes the risk of producing defective products by basing its analysis on data collected so there will be no inconsistency in quality.

Some of these are using machine learning for monitoring equipment health, computer vision for defect detection or identification, and AI algorithms for intelligent supply chain planning and demand forecasting.

The future of AI lies in more cutting-edge innovations, the main of which are generative AI for design, robotics AI for sophisticated operations, and AI application in supply chain in a way that is smarter and more adaptive.

AI positively impacts the supply chain by forecasting the demand, inventory management, disruption detection, and optimized logistics, and hence makes the supply chain more effective and economical.

Automated visual inspection for quality control, predictive analytics for maintenance, robotic automation for assembly lines, and AI-based systems for scheduling in assembly lines are some of the AI application areas.

Get In Touch